Swiss machining, a highly specialized area of manufacturing, plays a crucial role in producing precision parts essential for various industries. This guide explores the intricacies and advantages of Swiss-style machining, providing a comprehensive look at its mechanics, applications, and unique features. Discover why Swiss machining is chosen for complex and precise manufacturing tasks, the materials best suited for this process, and the industries that rely heavily on its capabilities.

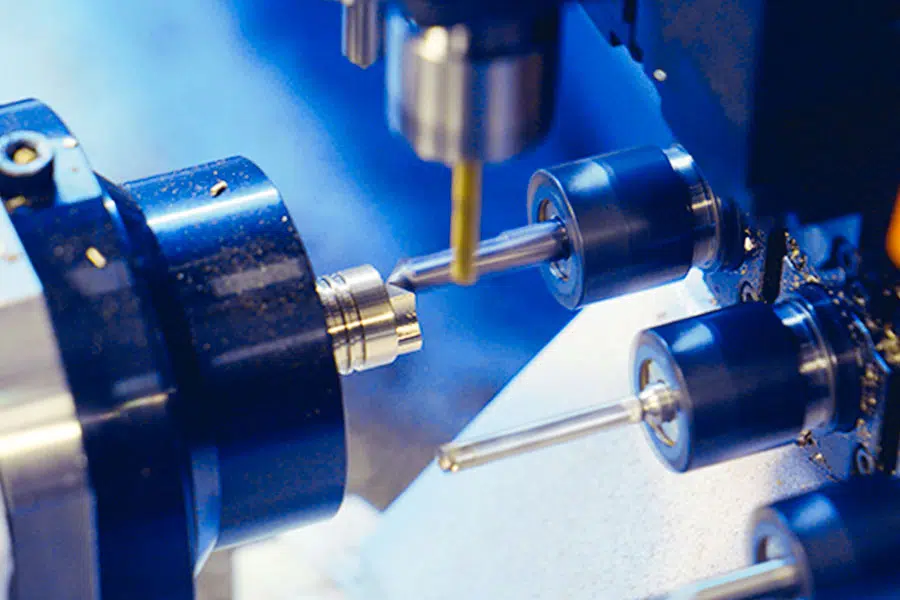

What Is Swiss Style Machining?

Swiss machining, often referred to as Swiss-type CNC machining, is a precision machining process used to manufacture small, complex parts with exceptionally tight tolerances. This method is distinguished by its use of a sliding headstock and guide bushing, ensuring the workpiece is supported very close to the cutting tools along the Z-axis. This setup minimizes deflection and vibration, allowing for high-precision machining of intricate parts. Swiss machining is renowned for its efficiency and ability to produce precision components rapidly and consistently, making it a staple in the manufacturing industry for detailed applications.

How and Where Did Swiss Machining Originate?

Swiss machining originated in the Swiss watchmaking industry in the late 19th century, developed to meet the demand for precise and intricate components in pocket watches. Over the decades, the technology evolved from manual machines to automated CNC processes, enhancing precision and production capabilities.

How Does Swiss Machining Work?

Swiss machining operates through a series of carefully orchestrated steps:

- Material Loading: A bar stock is loaded into the machine.

- Stabilization via Guide Bushing: The guide bushing holds the bar stock, ensuring stability.

- Machining Operations: Cutting tools perform various operations such as turning, drilling, and milling.

- Headstock Movement: The headstock moves along the Z-axis for dimensional accuracy.

- Cooling and Lubrication: Coolants manage heat, maintaining precision.

- Part Separation and Collection: The machined part is cut from the bar stock, readying the next section.

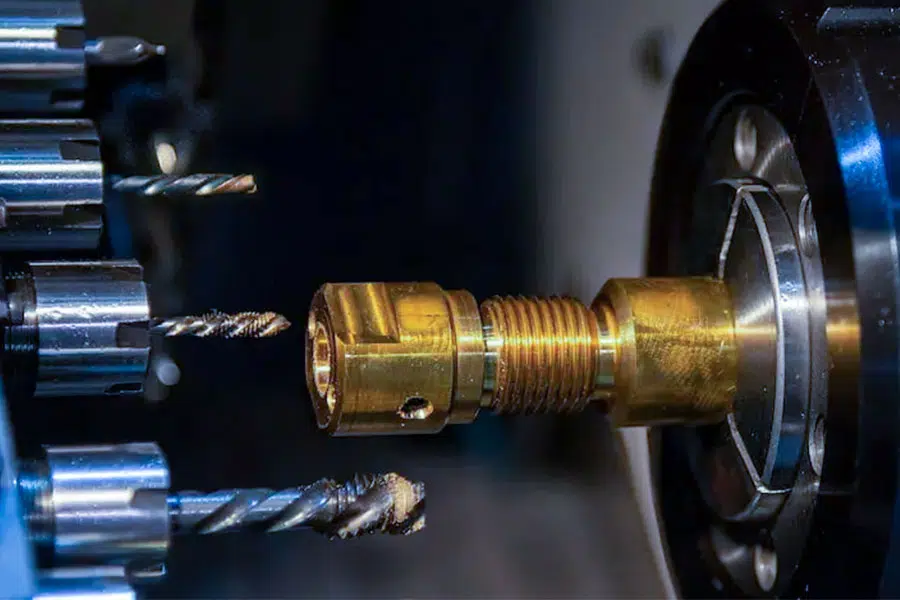

What Are the Unique Features of a Swiss Machine?

Swiss machines are designed to handle complex and precision-demanding tasks, featuring:

- Guide Bushing: Supports the workpiece close to the cutting tools.

- Sliding Headstock: Moves along the Z-axis for precise control.

- High-Speed Spindles: Enable high-speed machining.

- Multiple Tooling Stations: Allow simultaneous operations.

- Sub-Spindle: Completes back-end machining without re-fixturing.

- Live Tooling: Facilitates off-axis drilling and milling.

- Automatic Bar Feeder: Ensures continuous operation.

What Materials Are Suitable for Swiss Machining?

Swiss machining can process a wide range of materials, including:

- Stainless Steel: Corrosion resistance and strength.

- Titanium: High strength-to-weight ratio.

- Aluminum: Lightweight and easy to machine.

- Brass: Easy machinability.

- Copper: Excellent thermal and electrical conductivity.

- Plastics (PEEK, Nylon): Corrosion resistance.

- Carbon Steel: Cost-effective and durable.

- Nickel Alloys: Heat and corrosion resistance.

What Are the Industries That Utilize Swiss Machining?

Swiss machining is crucial in various industries:

- Medical Devices: For implants, surgical instruments.

- Aerospace: For aero-engine components, hydraulic manifolds.

- Automotive: For injector pins, transmission components.

- Electronics: For connectors, pins.

- Watchmaking: For gears, pins, complex parts.

How Accurate Is Swiss Machining?

Swiss machining is renowned for its exceptional precision, typically achieving tolerances within 0.0002 to 0.0005 inches. This precision allows industries like aerospace, medical, and electronics to rely on Swiss machining for parts where even a minuscule deviation could be detrimental to the function or safety of the final product.

How Much Does Swiss Machining Cost?

Swiss machining involves various cost factors:

- Machine Cost: Swiss CNC machines range from $100,000 to $500,000.

- Labor Costs: Skilled technicians cost $20 to $40 per hour.

- Material Costs: Metals like titanium and stainless steel range from $10 to $50 per pound.

- Electricity and Operational Costs: Averaging around $0.10 to $0.15 per kWh.

- Tooling and Consumables: Annual costs between $5,000 to $10,000.

- Maintenance and Downtime: Regular maintenance costs $1,000 to $3,000 per year.

How Long Does Swiss Machining Take?

The timeframe for Swiss machining varies based on part complexity, material, and precision required. Simple parts may take minutes, while complex designs can take hours. Setup time, material hardness, and production volume also influence the duration.

What Are the Advantages of Swiss Machining?

Swiss machining offers several advantages:

- Precision: Achieves tolerances as tight as 0.0002-0.0005 inches.

- Complexity: Produces intricate parts with ease.

- Efficiency: High-speed machining reduces production costs.

- Flexibility: Handles a variety of materials.

- Scalability: Suitable for both small and large production volumes.

- Reduced Waste: Precise cutting minimizes material waste.

- Surface Finish: Often eliminates the need for post-processing.

- Automation: Reduces manual labor and increases consistency.

How to Optimize Design for Swiss Machining?

To maximize efficiency and quality in Swiss machining:

- Minimize Material Waste: Optimize material usage.

- Enhance Part Design: Simplify designs to reduce machining steps.

- Model Drawing: Ensure clear model drawings with necessary dimensions.

- Standard-Sized Hole: Use standard drill sizes.

- Avoid Sharp Corners: Add radii to enhance manufacturability.

- Wall Thickness: Maintain consistent wall thickness.

What Are Common Design Mistakes in Swiss Machining and How to Avoid Them?

- Inadequate Material Allowance: Leave enough material for finishing.

- Over-Complexity in Design: Simplify where possible.

- Ignoring Machining Capabilities: Collaborate with machinists during design.

- Improper Tolerance Specification: Apply realistic tolerances.

How Does Swiss Machining Compare to Other CNC Techniques?

Swiss machining stands out due to:

- Precision and Tolerances: Achieves tight tolerances.

- Complexity of Operations: Performs multiple operations in one setup.

- Part Length and Diameter: Suited for small, long parts.

- Setup and Cycle Times: Longer setup but faster cycle times.

- Material Waste: Produces less waste.

- Cost Efficiency: More cost-effective for large production runs.

Why Is Swiss Machining Important for Precision Parts?

The precision offered by Swiss CNC machines ensures that each part meets stringent specifications with consistent quality and repeatability, making Swiss machining the ideal choice for components that require complex geometries and high-precision engineering.

How to Choose a Swiss Machining Service Provider?

When selecting a Swiss machining service provider, consider the following factors:

- Experience: Look for providers with a proven track record in Swiss machining.

- Capabilities: Ensure the provider has the necessary equipment and expertise to handle complex projects.

- Quality Assurance: Verify that the provider has rigorous quality control processes in place.

- Certifications: Check for industry-standard certifications, such as ISO 9001, which indicate a commitment to quality.

- Customer Service: Evaluate the provider’s responsiveness and willingness to collaborate.

- Cost: Compare pricing structures to ensure you are getting value for money.

What Are the Future Trends in Swiss Machining Technology?

Swiss machining technology continues to evolve, driven by advancements in automation, materials, and digital integration. Future trends include:

- Increased Automation: Enhanced automation capabilities to further reduce manual intervention and increase efficiency.

- Advanced Materials: Continued development of materials with superior properties, such as higher strength and better heat resistance.

- Smart Manufacturing: Integration with IoT and Industry 4.0 technologies to enable real-time monitoring and optimization of machining processes.

- Sustainability: Focus on eco-friendly machining practices and the use of sustainable materials.

- Customization: Greater ability to customize machining processes to meet specific industry needs and complex geometries.

What Are the Key Considerations for Using Swiss Machining?

When using Swiss machining, consider the following key factors:

- Material Selection: Choose materials that are well-suited for Swiss machining, taking into account their machinability and properties.

- Design Optimization: Optimize part designs to leverage the strengths of Swiss machining.

- Precision Requirements: Clearly define the required tolerances and surface finishes.

- Production Volume: Assess whether Swiss machining is cost-effective for the production volume.

- Lead Times: Plan for potential lead times associated with complex setups and high-precision requirements.

- Quality Control: Implement robust quality control measures to ensure consistency and accuracy.

How to Maintain and Ensure Safety in Swiss Machining Operations?

Maintaining and ensuring safety in Swiss machining operations involves:

- Personal Protective Equipment (PPE): Ensure that all operators wear appropriate PPE, such as goggles, gloves, and ear protection.

- Regular Maintenance: Conduct regular maintenance on machines to prevent malfunctions and ensure optimal performance.

- Training: Provide comprehensive training for operators on machine operation, safety protocols, and emergency procedures.

- Emergency Stop Mechanism: Equip machines with easily accessible emergency stop buttons to quickly halt operations if needed.

- Ventilation: Maintain proper ventilation in the workspace to manage fumes and coolant emissions.

- Tool Inspection: Regularly inspect cutting tools for wear and damage to prevent accidents and ensure precise machining.

Why Invest in Training for Swiss Machining Professionals?

Investing in training for Swiss machining professionals is crucial for several reasons:

- Skill Enhancement: Training ensures that operators are skilled in the latest machining techniques and technologies.

- Error Reduction: Well-trained professionals are less likely to make mistakes, leading to higher quality and fewer reworks.

- Efficiency: Skilled operators can optimize machining processes, reducing cycle times and increasing throughput.

- Safety: Training emphasizes safety protocols, reducing the risk of accidents and ensuring a safer work environment.

- Adaptability: Continuous training allows professionals to adapt to new materials, tools, and machining strategies.

What Are the Environmental Impacts of Swiss Machining?

Swiss machining, like other manufacturing processes, has environmental impacts that need to be managed:

- Energy Consumption: High-precision machining requires significant energy, contributing to the overall carbon footprint.

- Material Waste: Although Swiss machining produces less waste than some other methods, managing and recycling scrap material is essential.

- Coolant Use: Coolants used in machining can be harmful to the environment if not properly managed and disposed of.

- Emissions: Machining operations can produce emissions that need to be controlled through proper ventilation and filtration systems.

- Sustainability Practices: Implementing sustainable practices, such as using eco-friendly coolants and energy-efficient machines, can mitigate environmental impacts.

Conclusion

Swiss machining stands out as a highly precise and efficient method for producing complex parts with tight tolerances. This guide has covered its origins, operation, materials, applications, and advantages, highlighting why Swiss machining is essential for industries requiring detailed and high-precision components. For those seeking to leverage the benefits of Swiss machining, choosing the right service provider and investing in ongoing training are critical steps. As technology evolves, Swiss machining will continue to adapt, incorporating advanced materials, increased automation, and sustainable practices to meet future manufacturing demands.

Disclaimer

The content appearing on this webpage is for informational purposes only. LongSheng makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through LongSheng’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please contact to our for more information.

Team LongSheng

This article was written by various LongSheng contributors. LongSheng is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding,metal stamping and more.

FAQs

1. What materials are best suited for Swiss machining? Swiss machining is versatile and can handle materials such as stainless steel, titanium, aluminum, brass, copper, plastics (PEEK, Nylon), carbon steel, and nickel alloys, each chosen based on their specific properties and manufacturing requirements. 2. How does Swiss machining compare to traditional CNC techniques? Swiss machining offers superior precision and can perform multiple operations in one setup, making it ideal for small, complex parts with tight tolerances. It is more efficient and produces less material waste compared to traditional CNC machining. 3. What are the cost factors associated with Swiss machining? Costs include machine acquisition, labor, materials, electricity, tooling, consumables, and maintenance. Despite higher initial costs, Swiss machining is cost-effective for large production runs due to its efficiency and precision.