Casting is an important manufacturing process that involves pouring molten metal into a cavity designed in advance, also known as a mold, to create a solid, shaped object. This process is used in many industries including automotive, aerospace and construction due to its cost-effectiveness and versatility. Casting is a key process for producing components with complex details and precise measurements.

There are many options, including die casting, investment cast, sand casting, and others. Each method has its own advantages and can be used for different applications. Understanding how castings work and the different casting methods is essential for engineers and manufacturers who want to produce high-quality products. This article will cover casting, its importance, the major varieties, and how it is operated.

What is casting?

Casting is the manufacturing process where molten metal is poured in a mold, and then allowed to cool. The mold is then broken or ejected in order to remove the casting. This allows for the production of complex and intricate components with specific properties.

How does casting differ from injection molding?

Two distinct manufacturing processes are casting and injection molding. Injection molding is the process of injecting molten materials into a mold under high pressure in order to produce a solid object. Casting, on the other hand, uses gravity to force the molten metal into the cavity of the mold. The mechanisms and applications of these processes are different, offering unique solutions to various manufacturing requirements. For more information, see our guide on Injected Plastics.

What is the importance of casting in manufacturing?

Casting is important in manufacturing because it allows the manufacture of intricate and complex metal components at a cost-effective price. Casting allows for the production of multiple parts in a single casting. It simplifies the assembly process, streamlines inventory and reduces costs. Casting increases efficiency and productivity by eliminating the need for extensive joining or welding.

Casting Process Overview

Casting is a method of manufacturing that creates metal parts in the desired shape by pouring molten material into a mold, solidifying it and cooling it down to room temperature. The casting process is capable of producing intricate and complex parts regardless of their size.

Casting is able to produce metal parts that are isotropic in large quantities. This makes it ideal for mass production. To meet the needs of specific users, different types are available, which differ in terms of material and mold.

Casting processes: Different types

Each process has advantages and disadvantages depending on the requirements of the user.

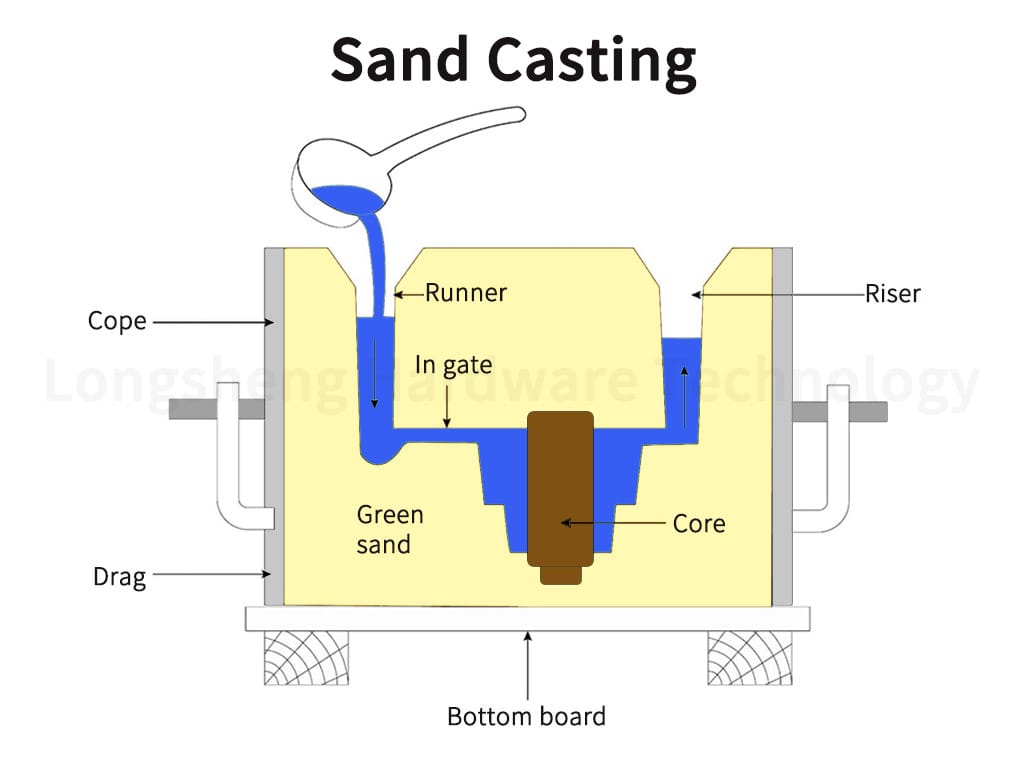

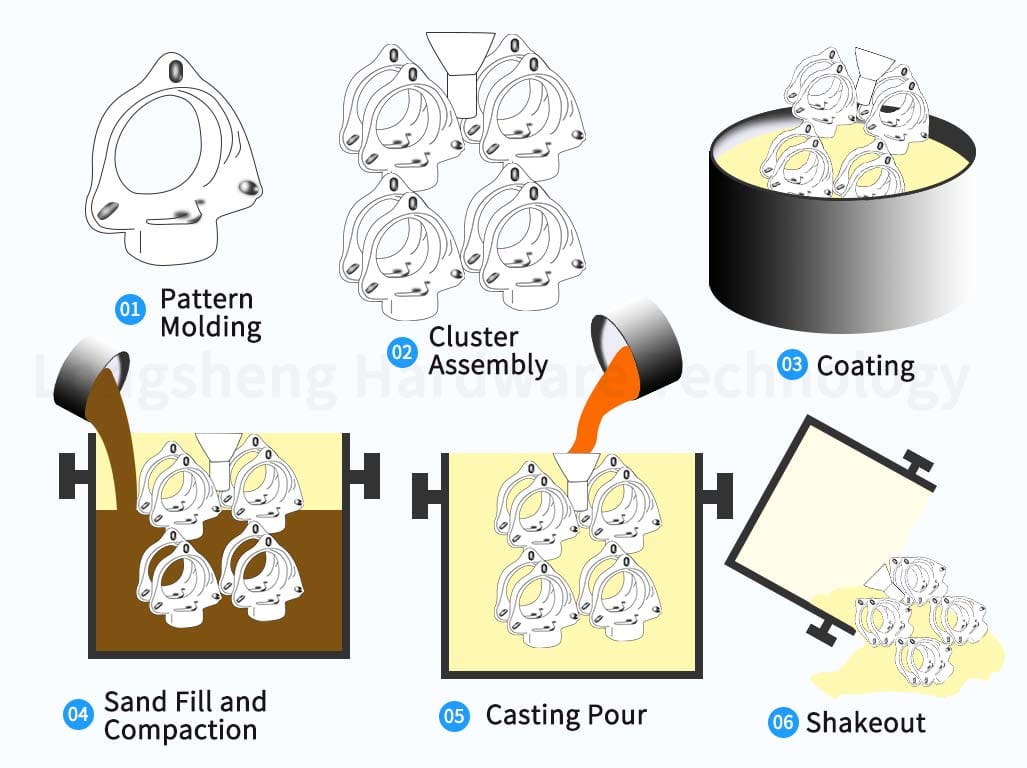

1. Sand Casting Process

Sand casting is an extremely versatile process. It can be used for any metal alloy, whether ferrous or not. This process is used in large industrial units for mass production of automotive metal castings like engine blocks and cylinder heads.

A mold made from silica-based material, such as naturally-bonded sand or synthetic sand, is used to create the mold’s smooth surface. The mold surface is divided into two parts: the upper half (cope) and lower half (drag). The pattern is filled with molten metal using a pouring pot and allowed to solidify. The final step is to trim off any excess metal for the metal casting.

Sand casting is a process that has both advantages and disadvantages.

| Advantages | Disadvantages |

| Costs of production are relatively low, particularly for low-volume production | Low accuracy compared to alternative methods |

| Fabrication of large components | This method is difficult to use for products that have predetermined weight and size specifications |

| Casting ferrous and non-ferrous alloys | This process produces products with a rough finish. |

| Recycling Ability | |

| Metals such as steel and titanium with high melting temperature |

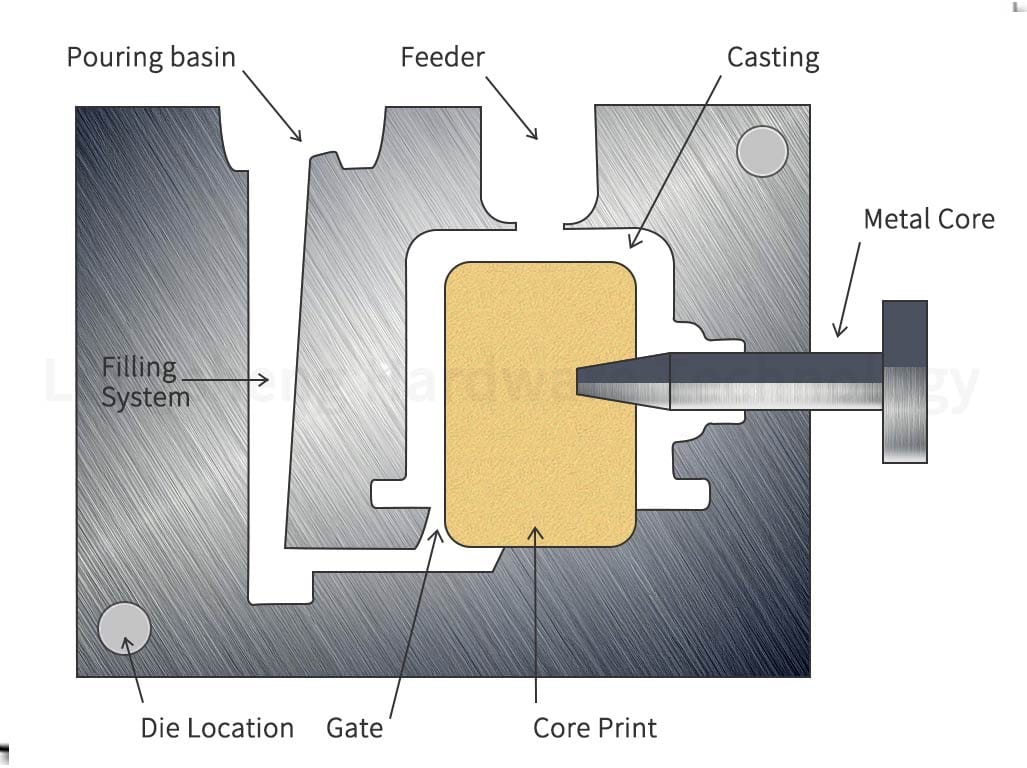

2. Gravity Die Casting

Gravity die cast, or permanent mold casting as it is also known, uses reusable metal molds, such as steel, graphite, etc. To fabricate metals and metal alloys. Metal casting is used to manufacture various metal parts, such as gears, wheel, engine pistons and pipe fittings.

Gravity is used to pour the molten metal directly into the cavity of the mold. The die can be tilted for better coverage. The molten material is allowed to cool, and then solidifies in the mold. This process is used to cast materials such as lead, zinc alloys, aluminum and magnesium alloys and certain bronzes.

In contrast to other pressure-casting processes, this casting process fills the mold from the bottom up. The process is more efficient than sand-casting, but it costs more. It is more expensive due to the metal molds. Below are its pros and cons.

| Advantages | Disadvantages |

| Rapid solidification improves the surface quality of products | Casting complex objects can be difficult |

| Castings are high-precision and have tight tolerance. | Molds cost more to manufacture |

| Reusable moulds reduce production costs and save time. | Sometimes, the ejection device used to remove the cast from the mold leaves a dent on the product |

| These products have better mechanical properties | |

| Production of thin walled product |

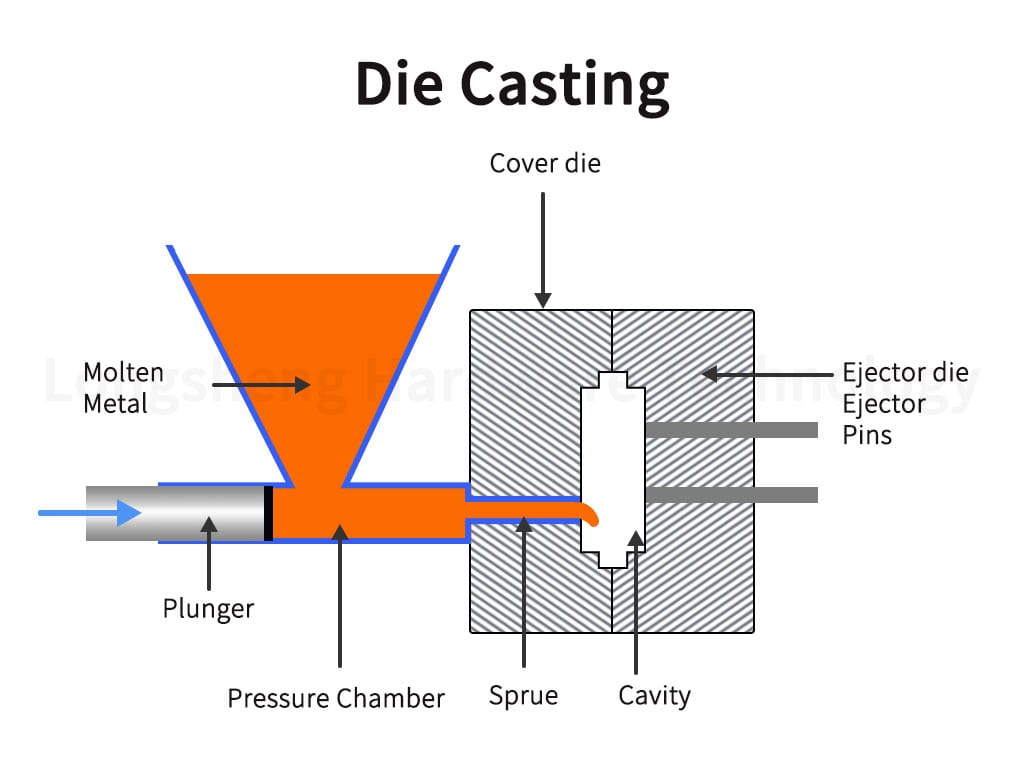

3. Pressure Die Casting

The pressure determines the type of die casting. There are two types of pressure die casting: low-pressure Die Casting and High-Pressure Die Casting. High-pressure die casting is preferred for complex geometries requiring high precision. Low-pressure die cast is the preferred casting method for large, simple parts.

This type of metal casting involves the injection of non-ferrous alloys, such as zinc and tin into a mold that is reusable and coated with lubricant. During the rapid injection, a high pressure is maintained to prevent metal hardening. After the rapid injection process is complete, castings are extracted and finished to remove excess material.

Gravity die casting is different from pressure die casting because of the way the metal mold is filled. Pressure die casting involves the injection of metal molten at high pressure into a metal mold. The molten material is solidified quickly to produce the desired product.

Below are a list of its advantages and disadvantages.

| Advantages | Disadvantages |

| High precision and dimension tolerance | High tool costs |

| High product efficiency and high quality | Limitation to non-ferrous metals |

| Post-casting machining is no longer required | It is difficult to guarantee the mechanical properties of the products. Therefore, it is not used as structural parts |

| Rapid cooling of molten steel in relation to higher production rates | A large investment is required to complete the setup |

| The process can be extended without replacing the die |

Select the Right Process for Your Application Between Die Casting and Sand Casting.

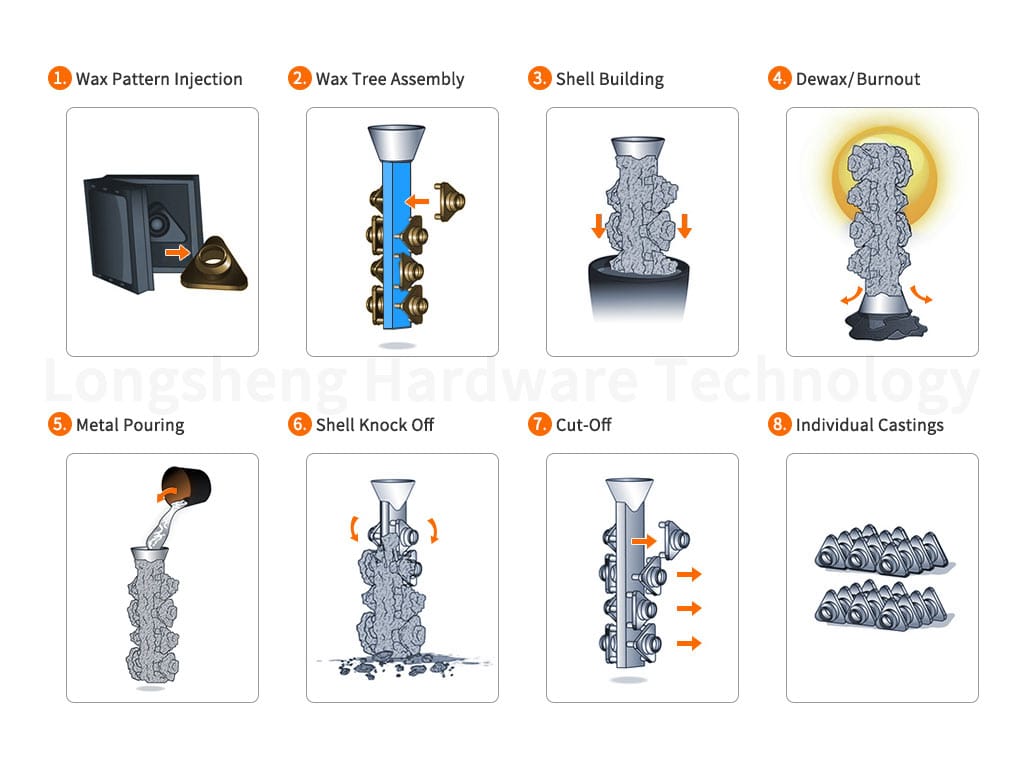

4. Investment Casting

Investment casting is also called lost-wax cast. It is a method that involves a wax pattern being coated with refractory materials and a binding agent. Then, molten metals are poured into the ceramic molds to produce metal castings. Investment casting, also known as lost-wax casting, is a labor-intensive and expensive process that can be used to make metal castings such as gears, bicycles trunks, moto disks, or spare parts for blasting machines.

The following is a list of its benefits and disadvantages.

| Advantages | Disadvantages |

| The machine can manufacture parts with thin walls and a high surface finish. | Requires labor for use |

| Reduces the need for post casting machining | The production cycle is longer |

| Casting alloys that are difficult to melt, such as stainless steels, thin steels, etc. | Molds are more expensive to manufacture |

| The shell mold can be broken to allow for castings at 90-degree angles. | Each casting cycle requires a new die for the creation and wax pattern. |

| High dimensional accuracy in products | |

| Mold shrinkage allowance |

5. Plaster Casting

The plaster cast process is very similar to the sand-casting method, but it uses a mix called “Plaster of Paris” for the mold. Plaster cools metals more slowly than sand due to its low thermal conductivity. This helps to achieve high accuracy for thin-section parts, in particular. It is not recommended for ferrous high-temperature materials.

Plaster mold casting can produce small castings as low as 30 grams and large castings as high as 45 kilograms. This process can be used to cast a component with a thickness of 1mm.

Find out more about the advantages and disadvantages of this product.

| Advantages | Disadvantages |

| Smooth surface finish | This process is more expensive than casting operations |

| Sand casting is more accurate in terms of dimensions than other methods | Aluminum and copper alloys are only suitable for limited applications |

| Casting complex shapes using thin walls | Plaster moldings may need to be replaced frequently |

| Not suitable for high melting materials | |

| Longer cooling times, effecting production rates | |

| Sand is a more stable material than sand. However, it can still affect the entire process. |

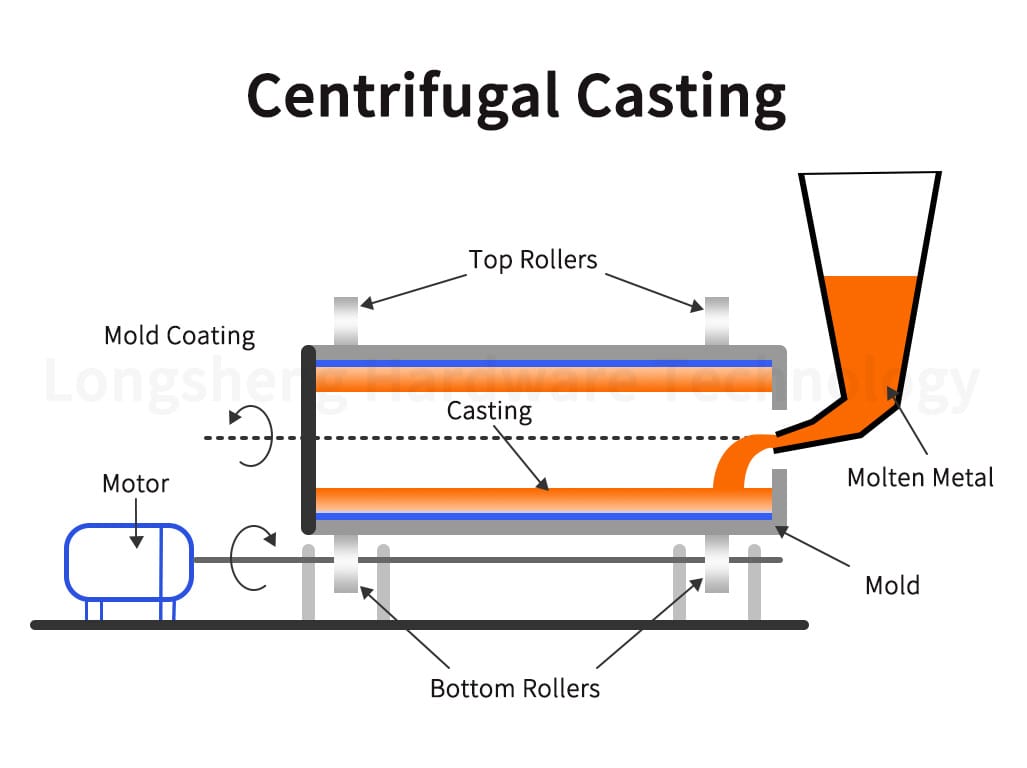

6. Centrifugal casting

Centrifugal cast, or rotocast, is an industrial process that uses centrifugal forces to manufacture cylindrical parts. This type of metal cast uses a spinning die that has been preheated into which the molten material is poured. The centrifugal force helps to distribute the metal molten within the die under high pressure.

There are three variations of centrifugal cast; the true centrifugal process, the semi centrifugal process, and the vertical centrifugal process. Semi centrifugal casts, unlike true centrifugal, have the mold filled completely using a sprue. In true centrifugal cast, the molten metal is forced to stick to the side due to constant rotation. Vertical centrifugal cast, as its name implies, is a process that uses directional molds.

Centrifugal casts are used to produce rotational shapes, such as cylinders. Particularly, bush bearings and clutch plates, piston rings and cylinder liners. The pouring of metal into the center of a mold also helps to reduce defects like blow holes, shrinkage and gas pockets. It is not appropriate for all metal alloys.

| Advantages | Disadvantages |

| Reduced wastage and improved process yields | The investment required for centrifugal casting is high |

| Castings with high density and virtually no defects | Need for skilled labor |

| It is easy to produce composite metal barrels and sleeves | Specific shapes production |

| No need for gates or risers |

7. Lost-Foam Casting

The lost-foam method is similar in many ways to investment casting, except that the pattern is made of foam instead of wax. After the pattern has been formed, the refractory ceramic is coated by dipping or coating, spraying or brushing. The molten metal then is poured in the mold to create the desired product.

The technique is applicable to a variety of materials, including alloy steel, cast iron alloys, ferrous alloys, etc. The lost-foam process is used to make products such as pump housings, fire hydrants and valves.

The production of lost foam casting is characterized by high precision. This process has some limitations that make it unsuitable to low-volume applications.

| Advantages | Disadvantages |

| High Precision Casting | Low volume production at high pattern costs |

| Allows flexible design | Low strength can cause distortion or damage to the pattern |

| Clean production | Multiple production processes and longer delivery times |

| High volume production can be economical |

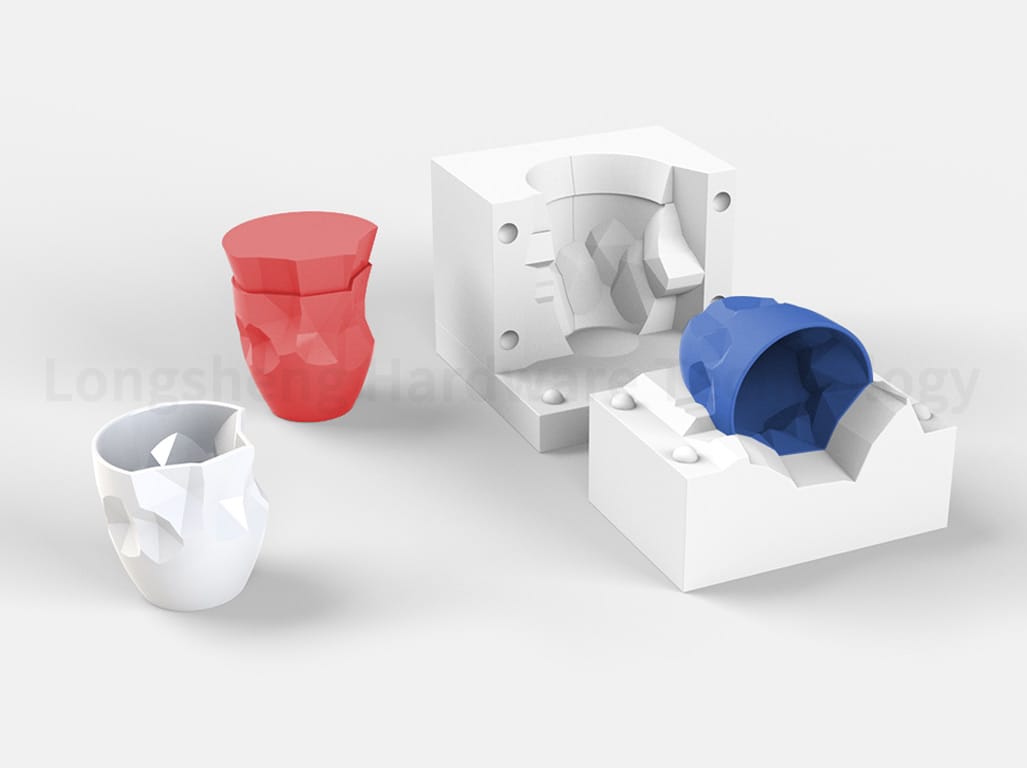

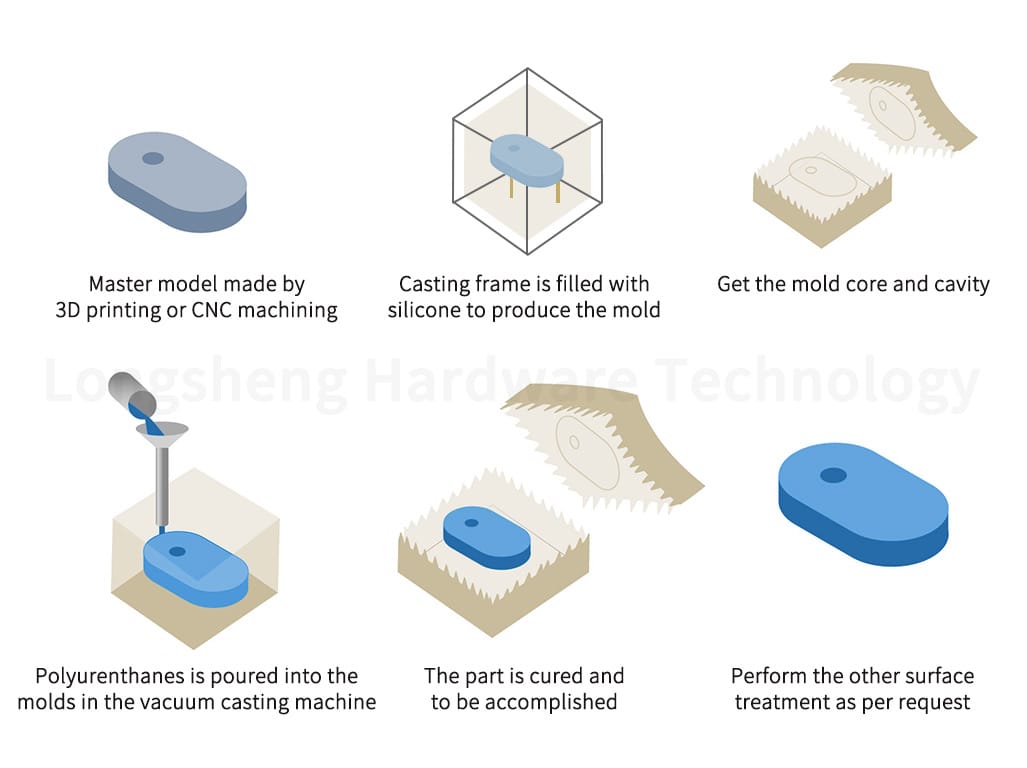

8. Vacuum Casting

Vacuum Casting is a type of casting that occurs under vacuum pressures of less than 100 bar to exhaust the gas from the mold cavity. This process involves pouring molten metal into the cavity of a mold in a vacuum chamber to remove bubbles and air. Vacuum evacuation of the die cavity helps to reduce the gas entrapment within the cavity. The metal is then cured and removed from the mold in a heated chamber.

The vacuum die casting process is popular in various industries including automobiles, aerospace, electronics, marine, telecommunication, etc. This manufacturing process is used to produce structural chassis components and automobile body parts.

| Advantages | Disadvantages |

| Die castings with reduced porosity and improved surface quality will have better mechanical properties. | High cost of tooling |

| Production of thin-walled products | Molds used for the process have a limited life span |

| It is possible to heat treat and weld products | Hollowness Issues |

| Low volume production suitable | |

| Hard tool finishing is not required | |

| Early stages of the air bubbles and pockets are reduced. |

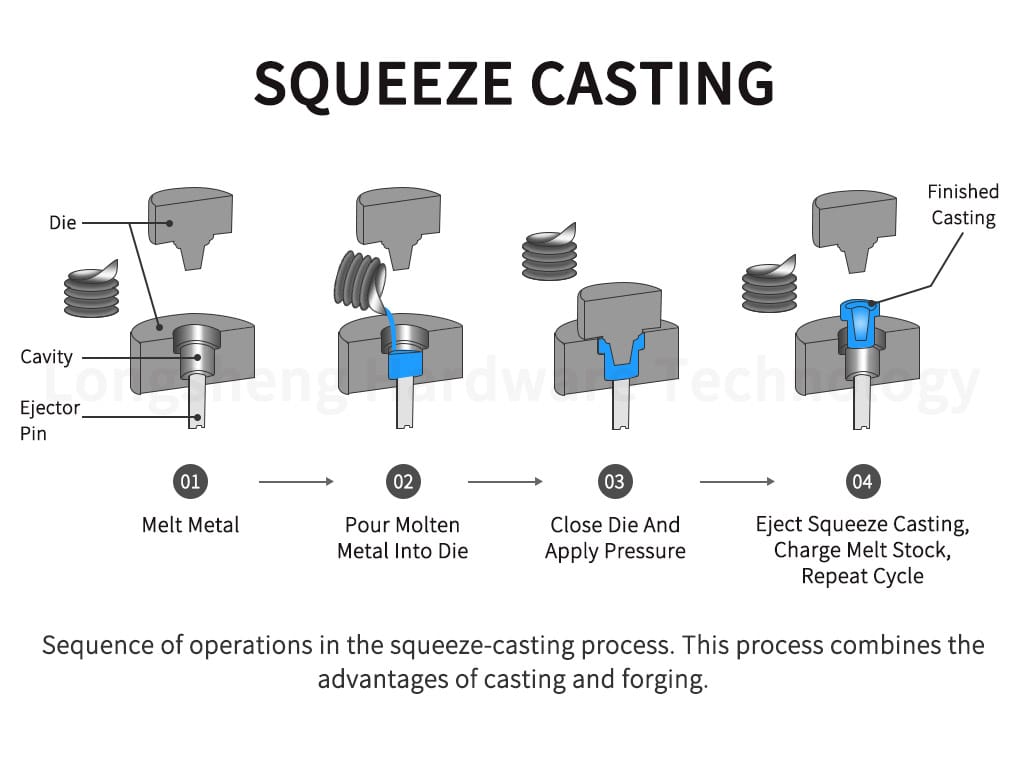

9. Squeezing casting

Squeeze casting or liquid forging is a hybrid metal-forming process which combines permanent mold casting with die forging into a single operation. This process involves injecting a certain amount of molten alloy into a mold and applying pressure to form it. The metal part is then heated to melting temperature, and removed from the die.

Squeezing die cast is an ideal process to use for parts that are safety critical in automotive systems. Space frame joints, aluminum front steer knuckles or chassis frames.

The advantages of both casting and forging are combined in this type of metal casting. The high pressure used during solidification, for example, helps to prevent shrinkage and pores. Due to the specific requirements for tooling, this process is not as popular in mass production as other casting methods.

| Advantages | Disadvantages |

| Eliminates internal defects such as pores, shrinkage hole and shrinkage porosity | Part geometry with less flexibility |

| Surface roughness | Lower Productivity |

| This can help prevent cracks from forming. | High-machining requirements |

| High strength components | The overall process is slowed down by the need for accurate control. |

| No waste of material |

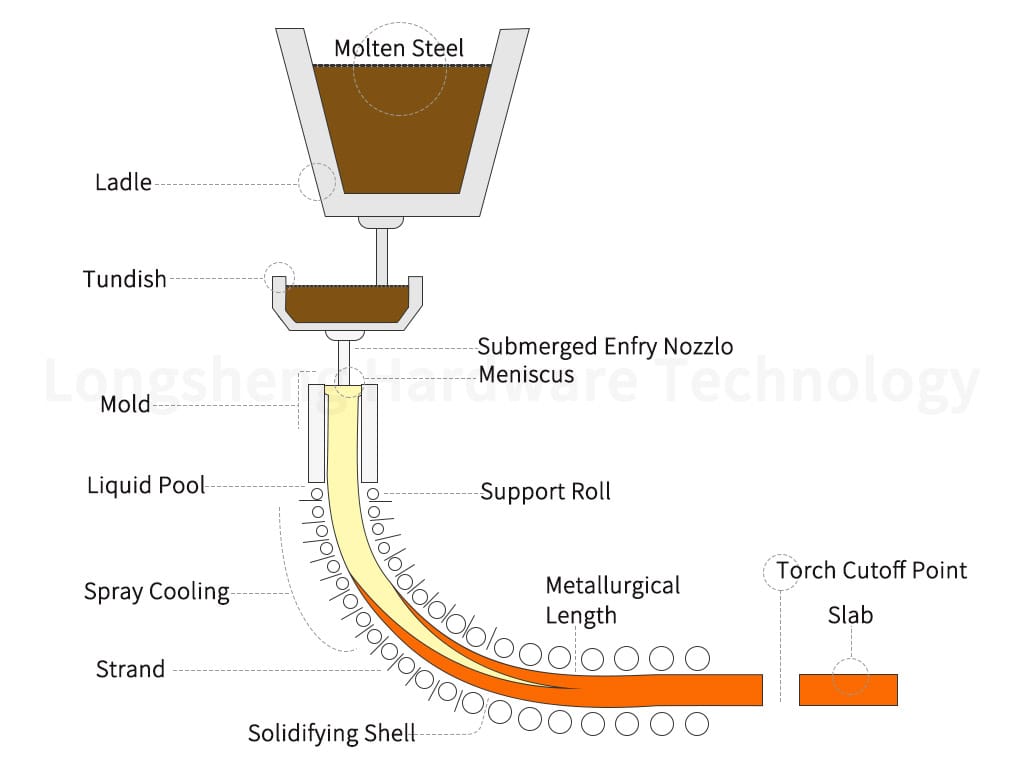

10. Continuous Casting

It allows for mass production of metal profiles with a constant section. This type of casting has become popular for the production of steel bars. Vertical casting can also be used to create semi-continuous castings like bars, billets, and ingots.

This process involves pouring molten steel at a controlled rate into an open-ended, water-cooled mold. The liquid metal inside the mold is allowed to cool and solidify, creating a metal surface. The metal solidifies from the outside out. After the process is complete, metal strands can be extracted continuously from the mold. Mechanical shears and oxyacetylene torch travels can be used to cut predetermined lengths from the product.

In general, products produced by continuous casting are homogeneous and consistent. They also tend to be dense. It is also limited to these applications. Other advantages and disadvantages include:

| Advantages | Disadvantages |

| Casting products are available in a wide range of sizes, ranging from thin strips to large billets and slabs. | Molds must be cooled continuously, or else center-line shrinkage will develop. |

| Continuous production reduces costs | Casting only simple shapes that have a constant cross section |

| Reduce material waste | Large ground space required and high initial investment |

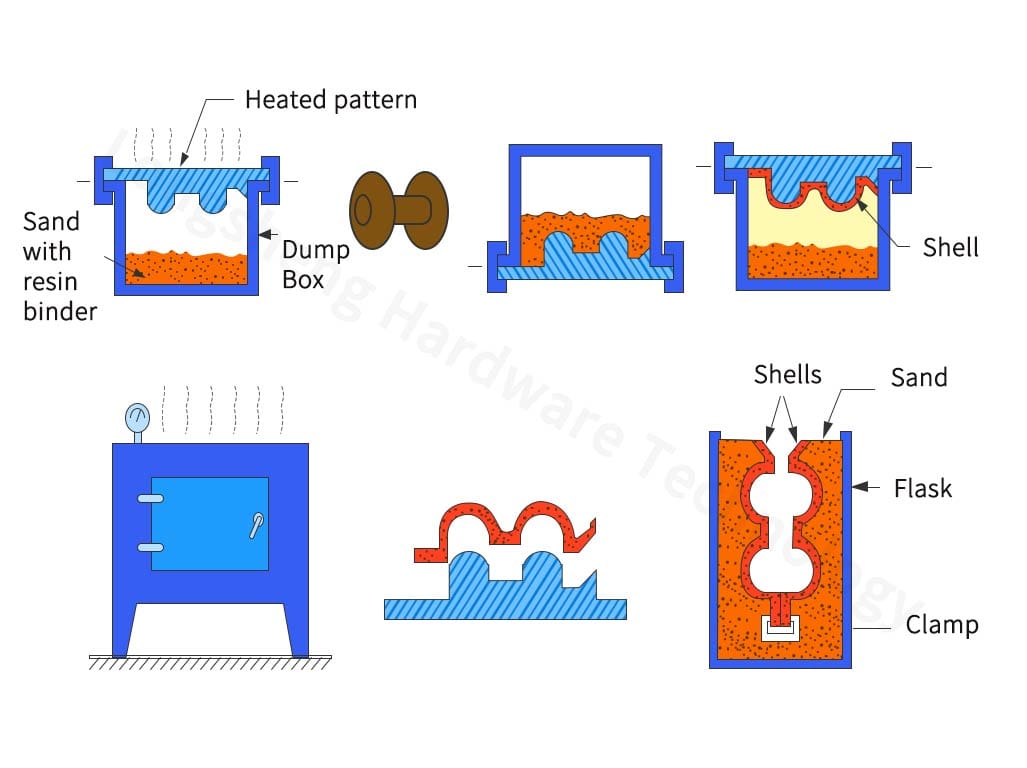

11. Shell Molding

Shell molding is a mold-casting process that can be discarded. The process is similar to sand casting, except that instead of using a flask filled with sand as the mold cavity, a hardened shell made of sand is used. The sand is finer and mixed with resin to be heated and hardened around the pattern.

Shell molding is used to make industrial products such as gearbox housings, connecting rods, small boats, truck hoods and cylindrical heads.

Casting products have a high level of surface finish, and are dimensionally accurate. The size and weight of the casting parts are the limitations of this type of casting. Other advantages and disadvantages include:

| Advantages | Disadvantages |

| Casting thin and complex parts | Small scale production is not suitable |

| Semi-skilled work | Size and weight restrictions |

| No additional machining is required | Large castings are expensive because of the special metal pattern. |

| Accounts for surface defects |

The Basic Steps in Different Casting Production

Casting processes are mainly based on a few basic steps, such as pattern-making, mold-making, selecting and pouring metal alloys, and finishing the cast part.

- Pattern Making

It is crucial to know the shape of the mold before you can create a design. Materials used for this include wax, sand or plastic, and even wood.

- Mold Making

The next step is to create various types of casting molds. A single-use mold is made of plaster, sand or ceramic shell. Each one has its own production process. Also, foam patterns or wax patterns are burned in a kiln.

- Select metal alloys

Alloys, either ferrous or not, are used to produce metal castings. Alloys consist of a chemical mix of elements that have the best mechanical properties for final casting applications. Ferrous alloys are steel, gray iron, and malleable iron. Non-ferrous metals are aluminum alloys and bronze.

- Melt and pour alloy

The next step after selecting the metal alloys is to pour the metal into the mold. This involves heating a solid metal in a crucible or furnace with an open flame until it melts. Pouring the molten material directly from the crucible can be done for small castings. For larger castings, the metal may need to be transferred into a larger ladle first before being poured into the mold.

- Finishing

After solidification the cast product is removed, and metal finishing done. The process of finishing may also include the removal or larger waste materials by scrubbing.

How Does Casting in Manufacturing Work?

Casting in manufacturing involves the process of pouring molten material into a mold to create the desired shape. The molten material solidifies and takes the shape of the mold, forming the final product. The mold can be made from various materials, such as: sand, plaster, or metal, depending on the casting method. After solidification, the casting is removed from the mold, cleaned, and further processed as needed.

What Is the Process of Casting?

The casting process, specifically sand casting, involves the following steps:

- Place the mold pattern, which determines the size and shape of the casting, in the sand. The sand (which includes additives) will take the shape of the pattern.

- Establish a gating system, consisting of a pouring cup and gates, to direct the molten metal into the mold cavity.

- Remove the mold pattern from the sand once the sand has taken its shape.

- Pour the molten metal, heated to the appropriate temperature, into the mold cavity through the gating system. The metal can be one of many elements or alloys such as: iron, steel, aluminum, and bronze.

- After pouring, the molten metal is left to cool and solidify within the mold. The cooling time varies depending on the type of metal used.

- Once the metal has cooled and solidified, open the mold to remove the newly formed metal casting. The mold patterns are typically reusable, but the molds themselves need to be remade for each casting.

How Long Does the Casting Process Take To Finish?

The duration of the casting process can vary significantly and is influenced by several factors. The time required for casting depends on: the size of the product, the specific type of casting performed, the sample size of production, and the level of labor involved in the process. Consequently, there is no fixed or standard time for casting. The time frame can range from as little as one hour to as long as 2–10 weeks, depending on these variables.

What Are the Common Materials Used in Casting?

Common materials used in casting include:

- Magnesium

Magnesium alloys are commonly used in casting due to their lightweight properties and good strength-to-weight ratio. They are often utilized in applications for which weight reduction is crucial, such as: aerospace components and automotive parts.

- Aluminum

Aluminum is a versatile casting material known for its excellent corrosion resistance, high thermal conductivity, and good mechanical properties. It is widely used in various casting methods, including: sand casting, die casting, and investment casting. Aluminum is utilized in industries such as: automotive, aerospace, and consumer goods. For more information, see our guide on the Physical Properties of Aluminum.

- Iron

Iron is a widely used casting material that comes in different forms, including gray iron and ductile iron. Gray iron is known for its good casting properties, high thermal conductivity, and damping capacity, making it suitable for applications such as: engine blocks, pipes, and automotive components. Ductile iron, also known as nodular or spheroidal graphite iron, offers higher strength, toughness, and ductility, making it ideal for applications requiring greater load-bearing capabilities.

- Zinc

Zinc is commonly used in die casting due to its low melting point, excellent flow characteristics, and dimensional stability. It is often chosen for casting intricate shapes and thin-walled components. Zinc castings find applications in various industries, including: automotive, electronics, and consumer products.

- Steel

Steel is a strong and durable casting material used for applications that require high strength, wear resistance, and impact resistance. It is suitable for heavy-duty components subjected to harsh conditions, such as: machinery parts, construction equipment, and tools. For more information, see our guide on What Makes Up Steel.

- Copper Alloys

Copper alloys, such as bronze and brass, are popular casting materials known for their excellent electrical conductivity, corrosion resistance, and thermal conductivity. They are commonly used in: electrical and plumbing components, decorative items, and musical instruments.

- Lead Alloys

Lead alloys are utilized in certain casting applications, primarily due to their low melting point and malleability. They are used in specialized industries, including: radiation shielding, battery manufacturing, and certain industrial applications. It is important to note that the use of lead is carefully regulated due to its potential environmental and health concerns.

What Are the Industrial Applications of Casting?

The industrial applications of casting are diverse and extensive. Here is a list of common applications:

- Chemical Process Equipment: Employed in the production of chemical process equipment such as: reactors, heat exchangers, and pumps.

- Automobile Casting: Produces engine blocks, cylinder heads, transmission cases, and other critical components.

- Plant Machinery: Casting plays a crucial role in the manufacturing of various components. Plant machinery refers to a wide range of equipment used in industries such as: manufacturing, power generation, oil & gas, and shipbuilding. Some specific applications of casting in plant machinery include: impellers, casings, and valve bodies.

What Are Examples of Casting Products?

Casting is a versatile manufacturing process that produces a wide range of products for various industries. Here are some examples of casting products:

- Hydrants, used for water supply systems.

- Firefighting equipment such as: fire hydrants, couplings, and fittings.

- Plumbing components like: pipe fittings, valves, and connectors.

- Components for military vehicles and transportation equipment, such as: engine parts, brackets, and structural elements.

- Electrical hardware components, including: electrical enclosures, connectors, and terminal blocks.

- Precision machinery parts, such as: gears, housings, and brackets.

How Durable Are Casting Products?

Cast metal products, especially those that have undergone heat treatment, are durable. Depending on the metal alloy and application, their service life might range from a few months to several decades. Once the service life of a casting ends, the cycle begins again. It is collected by a scrap yard, recycled, and recast into a new object.

Does the Casting Product’s Thickness Vary?

Yes, the thickness of casting products can vary. The casting process allows for the production of components with varying wall thicknesses, depending on the design requirements and the capabilities of the casting method. Different sections of casting can have different thicknesses to achieve the desired strength, weight, and functionality of the final product.

What Is the Future of Casting?

The future of casting holds significant potential with the integration of advanced technologies. Optical measuring systems, such as the ATOS 3D Digitizer, are revolutionizing the industry by enabling efficient and accurate measurement of complex surfaces. These systems eliminate the laborious and time-consuming nature of traditional measuring methods, providing full-field measurements and faster validation. Embracing such technological advancements will enhance productivity, quality control, and overall efficiency in the casting process.

Is Casting Still Used Today?

Yes, casting is still widely used today in various industries. It remains a popular manufacturing process for creating complex metal components with excellent strength and durability. Casting methods, such as: sand casting, investment casting, and die casting, continue to be essential in sectors like: automotive, aerospace, and construction.

What Are the Advantages of Casting?

Advantages of the casting process include:

- Ability to produce complex shapes easily.

- Versatility—a wide variety of metals and other materials can be cast.

- Cost-effectiveness, especially for small quantities.

- Capability to produce large-sized castings up to 200 tons.

- Cost and time savings compared to other manufacturing methods.

- Suitable for materials that cannot be mechanically worked.

- Simplifies the production of large and heavy components.

What Are the Disadvantages of Casting?

Disadvantages of the casting process include:

- The surface finish may require additional finishing operations.

- Limited mechanical properties compared to wrought materials.

- The possible presence of casting defects like porosity.

- The dimensional accuracy of castings can be compromised due to shrinkage during the solidification process.

- High initial tooling and equipment costs for certain casting methods.

- The casting process is typically restricted to metals with lower melting points.

LongSheng can help you with your casting needs

You must choose the best casting process for your product. LongSheng provides you with access to a professional team of engineers who have vast experience in various casting services such as Die Casting Services and vacuum casting. Our team’s expertise allows us to better advise you and respond to any questions you may have.

You can get a rapid quote online for your parts by uploading the design file into our online quotation platform. We offer the best products at competitive prices.