Injection and transfer molding are widely used in manufacturing plastic and rubber parts. Each method has unique advantages and applications, making them suitable for different production requirements. Below, we explore the key differences between these two molding techniques.

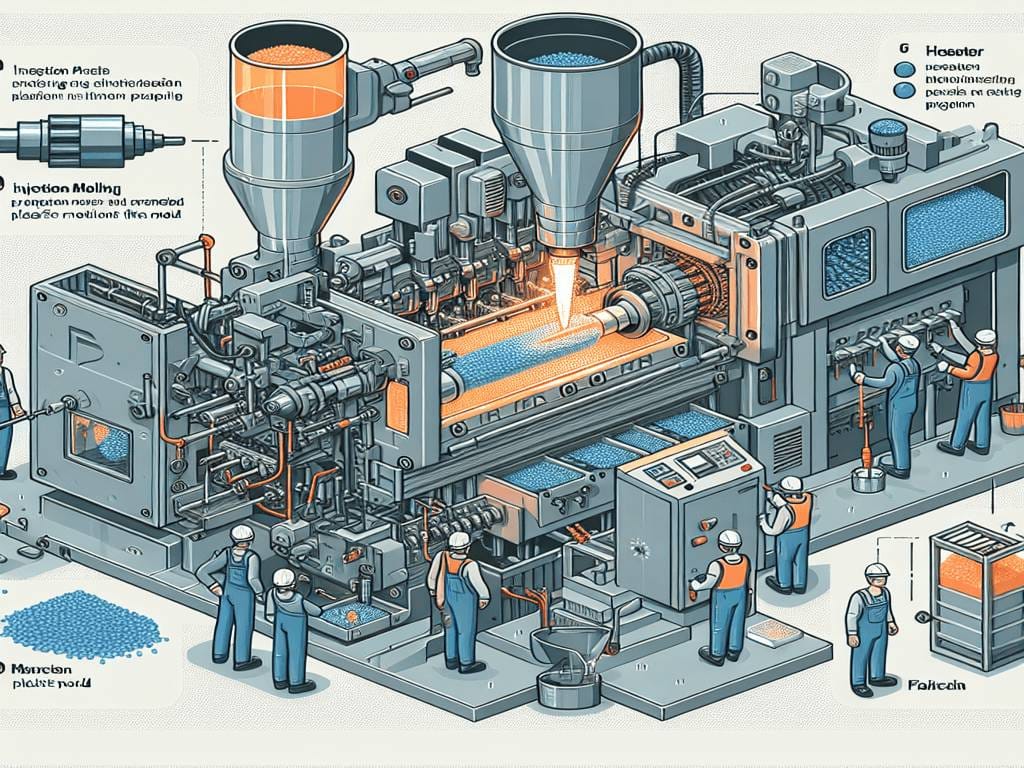

Injection Molding

Injection molding is a typical manufacturing process for high plastic and rubber parts volumes. It involves melting thermoplastic or thermosetting materials and injecting them into a mold cavity under high pressure.

Advantages of Injection Molding:

- High Efficiency: Injection molding is known for its fast production cycles, typically ranging from 30 seconds to a minute per cycle.

- Complex Parts: This method can create intricate shapes and designs, especially thin-walled casings for various equipment.

- Material Versatility: It can handle thermoplastic and thermosetting materials, including a wide range of polymers like PS, ABS, PA, PP, PE, PVC, and more.

- Low Waste: The process is designed to minimize material waste, contributing to cost savings and environmental benefits.

Disadvantages of Injection Molding:

- High Initial Costs: The upfront investment for injection molding machinery and tooling can be significant, ranging from $50,000 to $100,000.

- Design Limitations: Parts produced must have uniform thin walls and rounded corners to avoid defects.

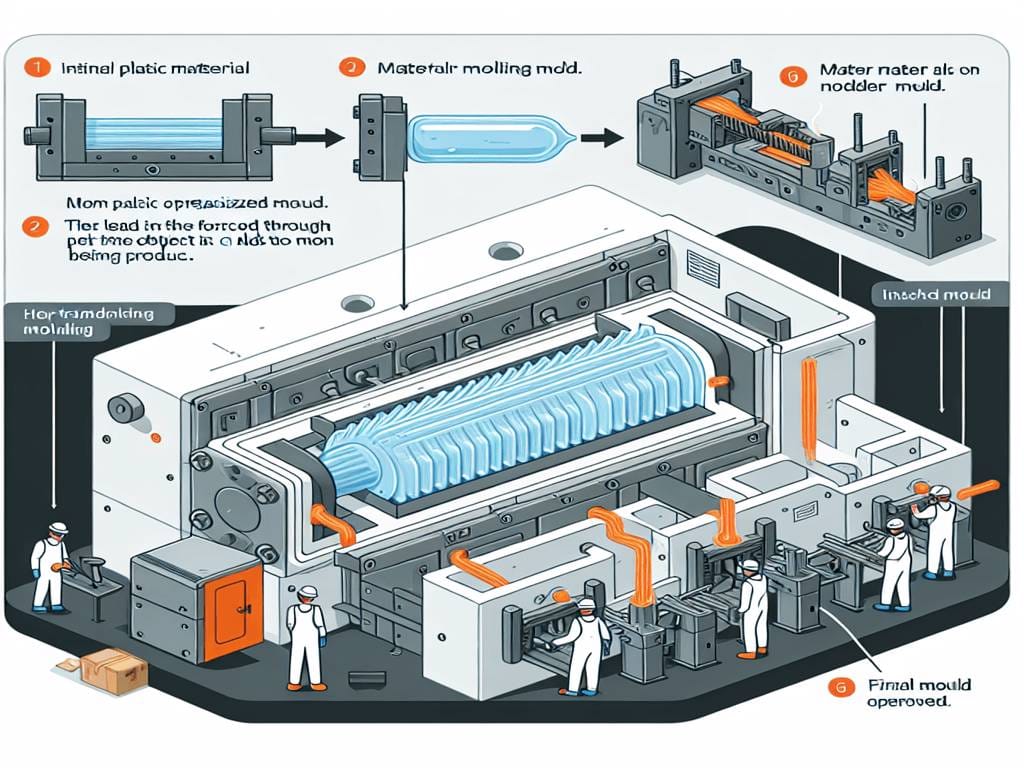

Transfer Molding

Transfer molding is a technique that combines the features of injection molding and compression molding. It is particularly suitable for thermosetting plastics and is used to encase electronic components or to produce parts with metal inserts.

Advantages of Transfer Molding:

- Inserts and Complex Designs: Transfer molding excels at embedding parts within the molded material and can handle intricate designs with sharper edges.

- Cost-Effective Tooling: The simple pot and plunger setup in transfer molding results in lower tooling costs than injection molding.

- Environmental Considerations: The process is environmentally friendly, and materials like glass beads can be recycled.

Disadvantages of Transfer Molding:

- Slower Production: The production speed of transfer molding is generally slower than injection molding due to the preheating and curing times required.

- Material Waste: There is potential for material wastage as some material may solidify in the sprue and overflow grooves.

- Limited Volume: Transfer molding machines typically have fewer cavities, making them less suitable for high-volume production.

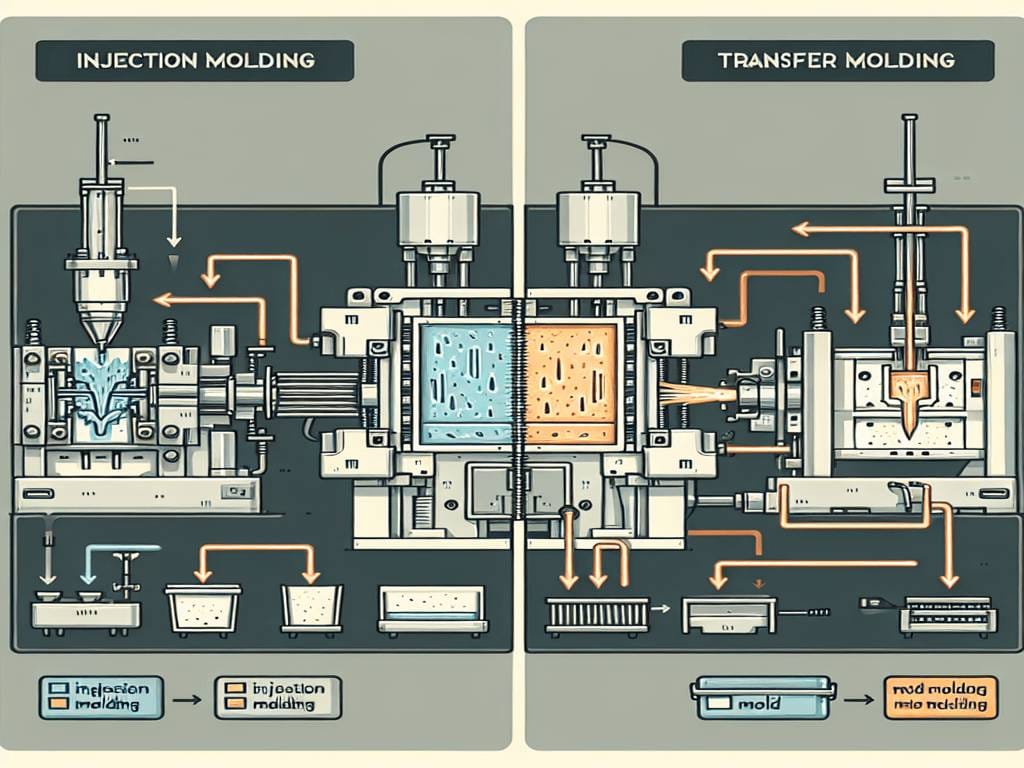

Key Differences:

- Materials: Injection molding is more versatile with materials, suitable for a wide range of thermoplastics and some thermosets. Transfer molding is primarily used for thermoset materials.

- Production Volume: Injection molding is better for higher quantities of more extensive, thin-walled parts. Transfer molding is ideal for smaller quantities and simpler molds.

- Cost: Injection molding has higher setup costs, while transfer molding is more cost-effective for smaller production runs.

- Design Flexibility: Transfer molding can produce parts with sharper edges and is better suited for adding metal inserts.

How do you choose between injection molding and transfer molding?

Transfer molding and injection molding both have their use cases and strengths. Overall, injection molding is an advanced technique with many applications. However, choose based on your needs and requirements.

Choose injection molding to bulk-produce thin-walled castings or complex structure thermoplastic components. Select transfer molding if you’re going to design rubber seals.

Are you seeking expert injection molding services? Look no further than LongSheng Custom Injection Molding Services. We craft plastic parts to meet specific size, complexity, and volume needs. Choose from over 30 thermoset and thermoplastic materials for your project.

Our facility has 30t to 1800t machines, perfect for prototypes and full-scale production. Benefit from our complimentary design consultation with every order. We promise quick delivery, with lead times starting at just 15 days.

Conclusion

When choosing between injection molding and transfer molding, manufacturers must consider factors such as the production volume, the parts’ complexity, the types of materials used, and the initial investment costs. Injection molding is ideal for large-scale production of complex parts, while transfer molding is more suitable for smaller runs with specific design requirements. Each method has pros and cons, and the choice ultimately depends on the project’s needs.