Are you aware that transfer molding can incorporate pre-made components within the molded material? Various electronics, medicine, and automotive industries rely heavily upon this molding technique to produce regular and over-molded parts. The process entails heating raw material and forcing it into a transfer mold using a plunger, resulting in the final product. Thus, it merges the concepts of injection and compression molding.

As we proceed, we’ll delve into the procedures of transfer molding, the evolution of the technology, its advantages and disadvantages, and its applications. Lastly, we’ll draw a comparison between this and other types of molding.

History of Transfer Molding

The birth of transfer molding technology can be traced back to the competitive landscape of marine vessel design and production following the Second World War. Initially, this technique was employed in 1946 to construct 28-foot-long glass fiber/polyester personnel boats for the US Navy, a feat credited to a private contractor. Since then, the technology has been on a continuous path of evolution up to the present day.

Let’s take a look at its progression over the decades.

| Year & Event | Description | Impact | Applications |

| 1946 – Invention | A glass fiber/polyester boat for the US Navy for the first time. | An alternative for compression molding. | Marine and Military |

| 1952s – 1956 Patent Registration | Registration of various patents regarding RTM molding mainly by Bristol Aircraft Limited | Acknowledgment of technology | Automotive and aerospace |

| 1960s – Demonstration | Development of machinery and some prototyping for aerospace parts | Became a key manufacturing process. | Mainly aerospace |

| 1970s – Technological Advancements | Progress in molding machinery, materials, precision, and efficiency. | Improvement in precision and efficiency. | Aerospace, automotive, industrial manufacturing, and electronics. |

| 1980s-2000s – Modernization | Significant modernization with computer-controlled processes and advancement in material sciences. | More control over the process | Various Sectors – complex parts with high-quality |

| 2000s-Present – Contemporary Developments | Ongoing developments in technology for versatility and efficiency. | Adaptation to modern manufacturing requirements, AI monitoring | Broad Applications – Precision components and advanced materials |

What’s Transfer Molding?

Transfer molding is a manufacturing process where heated material is forced from a chamber into a mold to create a part. It combines compression and injection molding and is commonly used to encapsulate delicate electronic components. The process begins with a pre-measured amount of material loaded into the chamber, and then a plunger is used to force the material into the mold cavity. The final part can be removed once the material has cooled and hardened. This method is popular in the electronics, medical, and automotive industries for producing regular and over-molded parts.

Advantages of Transfer Molding

Transfer molding offers several advantages, including:

-

Precision: It allows for high precision and detailed molding, making it suitable for complex designs.

-

Speed: The process is relatively quick, which can increase production rates.

-

Material Efficiency: There is less material waste compared to other molding methods, as the exact amount of material needed is loaded into the chamber.

-

Versatility: It can be used with various materials, including plastics and metals.

-

Protection: The process encapsulates components, protecting the environment.

-

Over-molding: It allows for over-molding, where a pre-formed part is placed into the mold, and additional material is molded over it.

-

Lower Labor Costs: The process is mainly automated, reducing labor costs.

-

High Quality: The high-quality parts have a good finish, reducing the need for post-production work.

Disadvantages of Transfer Molding

Despite its numerous advantages, transfer molding also has some disadvantages, including:

-

High Initial Costs: The molds used in transfer molding can be expensive to produce, especially for complex parts.

-

Limited to Smaller Parts: The process is typically used for smaller parts, as more significant parts may not form correctly.

-

Longer Setup Time: It can take longer to set up the process than other molding methods.

-

Material Limitations: Not all materials are suitable for transfer molding, particularly those with high melting points or that are not polite.

-

Maintenance: The molds require regular maintenance and can wear out over time, leading to additional costs.

-

Less Flexibility: Changes in design or material can require a new mold, reducing flexibility in production.

-

Risk of Trapped Air: There’s a risk of trapped air, which can lead to defects in the final product.

How Does Transfer Molding Work?

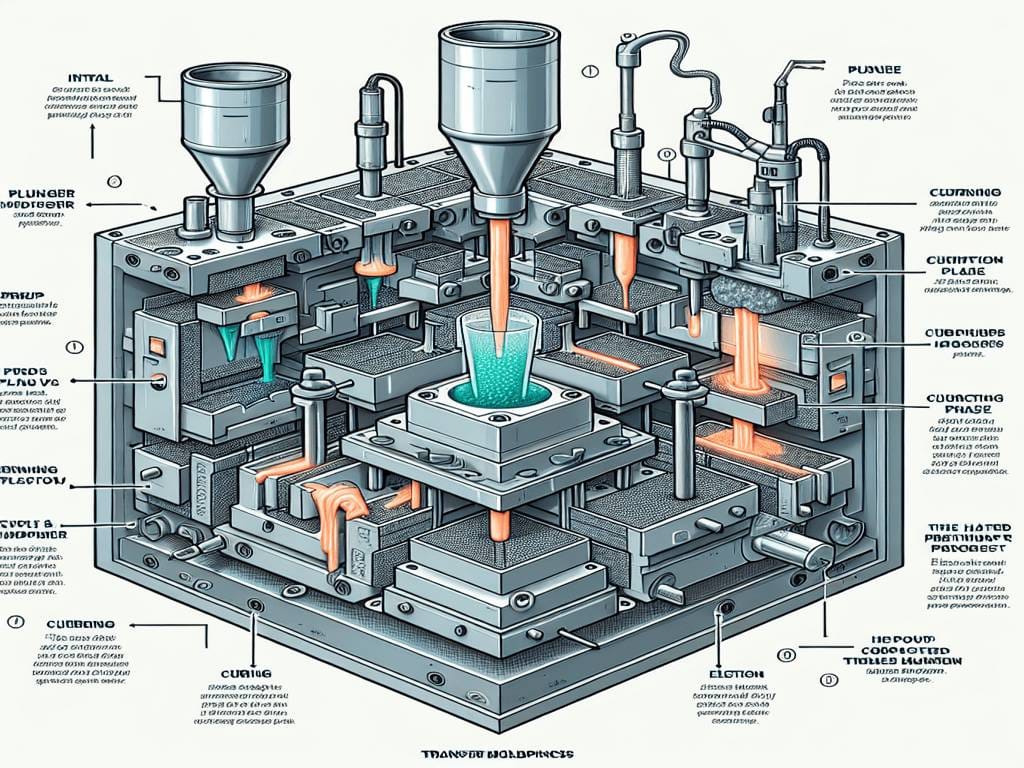

Transfer molding is a more straightforward process compared to other manufacturing techniques. As highlighted earlier, it involves placing and heating the raw material in a distinct chamber, typically located in the upper section of the mold. This material is then pressed into the mold. Let’s start by gaining a deeper understanding of the transfer molding setup.

| Component | Description | Function |

| Plunger | It applies pressure to the molding compound. | Positions above the pot and push the material into the mold cavities. |

| Pot & Heater | A transfer chamber or pot is there for placing the molding material | A heater surrounds the pot for heating purposes. |

| Upper and Lower Parts of the Mold | Two halves come together to form the mold cavity in the lower part of the setup. | The upper part is where material enters, and the lower part forms around the core. |

| Hinge | Allows the molding compound to cavities by opening the sprue. | It allows the transfer of the feed into the mold after heating. |

| Extraction Pin | Facilitates the ejection of the final product from the mold. | Ensures safe and efficient removal after curing. |

How does the process unfold, or how does the transfer molding function utilize this setup? The explanation can be found in the sequential steps that occur.

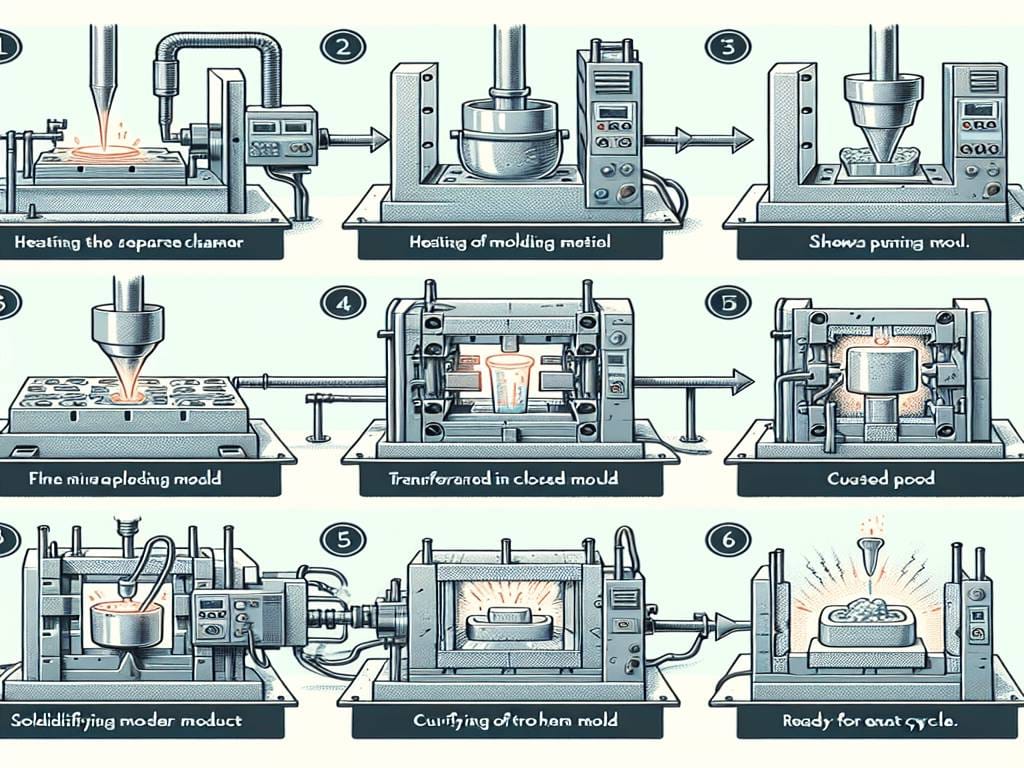

The process of Transfer Molding using a specific setup takes place in the following chronological steps:

-

Material Preparation: The thermosetting material is pre-measured and preheated in a chamber, also known as a “pot.”

-

Mold Preparation: The mold is prepared and secured. It comprises two halves – the bottom half, which contains the cavity where the material will be injected, and the top half, which applies pressure during the injection process.

-

Material Transfer: A hydraulic plunger forces The heated material into the mold cavity through a sprue hole.

-

Curing: The material is left to cool and harden within the mold. This is done under high pressure to ensure the material fills the intricate details of the mold.

-

Ejection: The final product is ejected from the mold once the material has hardened.

-

Trimming: Any excess material known as “flash” is trimmed to finalize the product.

This process is repeated for each new part that is produced. Transfer molding is commonly used for precision parts, encapsulation of parts such as electronic components, and molding with inserts. It offers advantages like lower pressure requirements, shorter cycle times, and the ability to mold intricate parts with tight dimensional tolerances.

Common Thermosetting Resins Used in Transfer Molding

Transfer molding procedures can work with thermoplastics, thermosets, and rubbers, but thermoset resins are predominantly used.

Here are some materials used in transfer molding:

-

Epoxy Resins: These are highly versatile and used in various applications due to their excellent mechanical properties and good chemical resistance.

-

Phenolic Resins: Known for their high heat resistance and mechanical strength, they are often used in high-intensity applications.

-

Polyester Resins: These resins are known for their excellent balance of mechanical, chemical, and electrical properties.

-

Melamine Resins: These applications require excellent hardness, gloss, heat, and solvent resistance.

-

Polyurethane Resins: These are known for their excellent toughness and flexibility.

-

Silicone Resins: These are used in applications that require high-temperature performance and excellent electrical properties.

Each of these resins has its unique set of properties, making them suitable for different applications in transfer molding.

Applications of Transfer Molding

Transfer molding caters to the diverse manufacturing needs of various sectors due to its material versatility, ability to handle complexity, insert molding feature, precision, and superior surface finish.

Let’s explore some specific products produced through transfer molding across different industries.

| Industry | Product or Part Examples | Why Transfer Molding? |

| Electronic Components | Switches, Insulators, Connectors, Circuit Boards, Encapsulations for Coils, Transformers, and Lip-seals for eclectic motors. | It is ideal for encapsulating delicate components, providing insulation, and protecting against environmental factors essential in the electronic and electrical industry. |

| Medical Devices | Syringes, Catheters, Housings for Implants, Disposable Medical Equipment | It enables the production of sterile, biocompatible components with the precision necessary for medical use. |

| Automotive Parts | Seals, Gaskets, Dashboards, Door Handles, Vibration Isolators, Engine Components, Spark Plug Wires | It produces durable parts with high dimensional accuracy and can withstand harsh conditions. |

| Consumer Goods | Toys, Grips, Handles, Keypads, Sporting Components, and Housings for Electronic Devices | Allow for manufacturing diverse consumer goods with complex shapes and high-quality finishes. |

| Rubber Products | Grommets, Washers, O-rings, gas valve interface, and Metal-to-rubber Face Seals for the Natural Gas Industry. | Rubber transfer molding is suitable for detailed and complex shapes with precision and consistency. |

Transfer Molding Variations

There are several variations of the transfer molding process, including:

-

Resin Transfer Molding (RTM): This is a low-pressure process where the resin is injected into a closed mold to saturate the fibers thoroughly.

-

Vacuum Transfer Molding (VTM): In this process, a vacuum is used to draw the resin into the mold, which helps to reduce voids and improve the quality of the part.

-

High-Pressure Transfer Molding (HPM): This process involves injecting the resin into the mold under high pressure, which helps ensure complete filling and can improve the part’s mechanical properties.

-

Compression Transfer Molding: In this process, the material is preheated and placed into the mold, and then pressure is applied to force the material to flow and fill the mold.

Comparison with Other Molding Processes

Transfer molding is often compared with other processes, such as injection and compression molding. Here’s a brief comparison:

-

Transfer Molding vs Injection Molding: Transfer and injection molding are similar. However, transfer molding is more suitable for encapsulating delicate parts, as the molding material is not subjected to high shear rates. On the other hand, injection molding is more efficient and has a faster cycle time, making it more suitable for high-volume production.

-

Transfer Molding vs Compression Molding: Transfer molding is a variant of compression molding. The main difference is that in transfer molding, the material is heated and transferred to the mold in a separate chamber before being compressed, which allows for more precise control over the material and can result in parts with more complex geometries and tighter tolerances. Compression molding, on the other hand, is more straightforward and less expensive but may not be suitable for more complex parts.

Table: Compression vs Injection vs Transfer Molding

| Criteria | Compression Molding | Injection Molding | Transfer Molding |

| Precision | Good precision. | Very high precision | High precision |

| Mold Complexity | Relatively simple molds. | Complex molds | Moderately complex molds |

| Materials | Primarily thermoset polymers and composites | Thermoplastics, thermosets composites, and elastomers. | Primarily thermoset polymers |

| Production Volume | Medium to high volumes | High-volume production | Best for low to medium volumes |

| Surface Finish | Good surface finishes | Excellent surface finishes | Smooth finish |

| Tooling Cost | Lower | Higher | Moderate |

| Structural Strength | Good | Excellent | Excellent |

Choose LongSheng Molding Services for Plastic Parts

The transfer molding process requires meticulous attention to detail and a sequence of steps, necessitating expertise and appropriate tooling to create high-quality plastic components. This is where LongSheng’s proficiency stands out. Our experienced engineers utilize their vast knowledge and state-of-the-art plastic molding facilities to convert your unique design specifications into functional, superior plastic parts.

At LongSheng, we value precision and the need for tailored solutions. Our injection molding and comprehensive plastic part services are designed to meet various industries’ specific requirements, including automotive, healthcare, consumer electronics, and more. We work collaboratively, aiming to deliver results that fulfill and surpass expectations.

Initiating a project with us is straightforward. Share your design vision, and we’ll handle the rest. Please request a quote today and discover how our plastic molding services can add exceptional value to your upcoming project.

FAQs

-

What is transfer molding? Transfer molding is a manufacturing process where pre-measured amounts of uncured plastic or rubber material are preheated and loaded into a portion of the mold. The material is then forced into the cavity, curing into the final part.

-

What are the variations of transfer molding? Variations of transfer molding include Resin Transfer Molding (RTM), Vacuum Transfer Molding (VTM), High-Pressure Transfer Molding (HPM), and Compression Transfer Molding.

-

What are the advantages of transfer molding? Transfer molding offers several advantages, such as excellent dimensional accuracy, high production rate, the ability to mold large parts, and the ability to encapsulate delicate parts.

-

How does transfer molding compare to other molding processes? Transfer molding is more suitable than injection molding for encapsulating delicate parts. Compared to compression molding, transfer molding allows for more precise control over the material and can result in parts with more complex geometries and tighter tolerances.

-

What industries use transfer molding? Transfer molding is used in various industries, including automotive, healthcare, consumer electronics, and more.

-

What materials can be used in transfer molding? Many materials can be used in transfer molding, including thermosetting plastics, elastomers, and some thermoplastics.

-

What are the limitations of transfer molding? Some limitations of transfer molding include higher tooling costs, difficulty molding large parts with high precision, and not being suitable for all types of materials.